Pipelines And Surface Facilities: ECHELON Software Features A Native Facility Network Solver (FNS)

Surface facility network solvers improve reservoir simulation models by providing crucial back-pressure information for wells to the simulator.

Surface facility network solvers improve reservoir simulation models by providing crucial back-pressure information for wells to the simulator.

Posted in: ECHELON Software

Reservoir engineers develop and evaluate field depletion and management strategies with the help of ECHELON, an advanced numerical reservoir simulator. ECHELON forecasts the subsurface’s response based on the field’s history, planned development, and estimated production and injection allocation amongst wells, by solving complex time-dependent equations derived from a full physics model of the real world. The well allocation is computed by ECHELON’s field scheduler, a software component that uses a comprehensive set of rule and priority based algorithms to determine guide rates and allocate production and injection to meet individual well and well group constraints. The computation of guide rates is based on well potentials, a common practice in the simulation community. The approach achieves realistic results, especially during the production plateau phase, where most wells need to be choked below their maximum potential to meet constraints. In this blog article, we describe how ECHELON’s network simulator, FNS, can further improve the results of the allocation process.

Maybe the best way to answer this question is to point to the things that the reservoir simulator does not do. Beyond the wells, a large network of interconnected pipelines, valves, compressors and/or pumps leads reservoir fluids to separation units and transports water and/or gas towards injection wells. Fluids traveling through the network experience pressure drops, e.g. due to friction and hydrostatic effects, with compressors and pumps locally increasing flow rate and pressure. All of this is neither “seen” by the reservoir simulator nor the field manager because well pressures and rates are discrete mathematical boundary conditions to the simulation model. In other words, what lies beyond the wells is not part of the standard reservoir simulation model. FNS “looks” at the problem from the other direction. It computes pressure drops and flow rates inside the surface facility network, based on a network boundary condition and well performance curves computed by the reservoir simulator. To be more precise: The reservoir simulator marches through time, computing the reservoir’s response based on discrete well boundary conditions that are determined by a set of rules and time-dependent constraints. The rules try to maximize hydrocarbon production under the constraints. FNS - on the other hand - solves for network flow-rates and pressures based on the network’s discrete boundary condition and well productivity at each given time. Hence, FNS computes the field’s capacity rate by ignoring constraints. In the next two paragraphs, we explain how the reservoir simulator and FNS can work together to provide more reliable production forecasts.

We must look at the assumptions behind the standard allocation process. For brevity, we restrict our discussion to production streams. Most field development scenarios start with a plateau phase, where the production capacity is larger than the field’s separation or water/gas handling capacity or some other constraint, e.g. a maximum daily rate constraint for filling the storage tanks inside a FPSO.

Since the combined capacity from the wells is larger than the plateau rate, the field scheduler will choke back individual wells, or groups of wells, based on certain heuristics and rules. For instance, if the total liquid production is too high, the field manager may decide to choke back wells with high water-cut to promote hydrocarbon production and reduce water production. The rules are far from trivial because of possible conflicting constraints and balance requirements between injection and production. Nevertheless, in the end, the field scheduler’s solution to the allocation problem is to choke back individual wells at varying degrees. In the real world, choking a well to a certain rate translates into increasing the wellhead pressure by means of a valve. As long as this pressure is high enough, such that friction and hydrostatic effects further downstream do not reduce the fluid pressure below the fixed separator inlet condition, the computed solution is realistic. However, if the reservoir (and required wellhead) pressure declines, rates assigned to individual wells may become unsustainable.

As noted earlier, FNS computes maximum rates for the unconstrained network flow problem. As part of the solution, FNS computes choke pressure drops for individual wells based on the network back-pressure and the inflow performance curves provided by the reservoir simulator for the given point in time. The wellhead pressure together with the choke pressure provides ECHELON with a more accurate estimate of the well’s operating range to guide the allocation process. Since FNS takes into account the backpressure that the network exercises onto the wells, the FNS supported allocation process will result in a more conservative allocation, reducing the risk of overestimating reservoir fluid production.

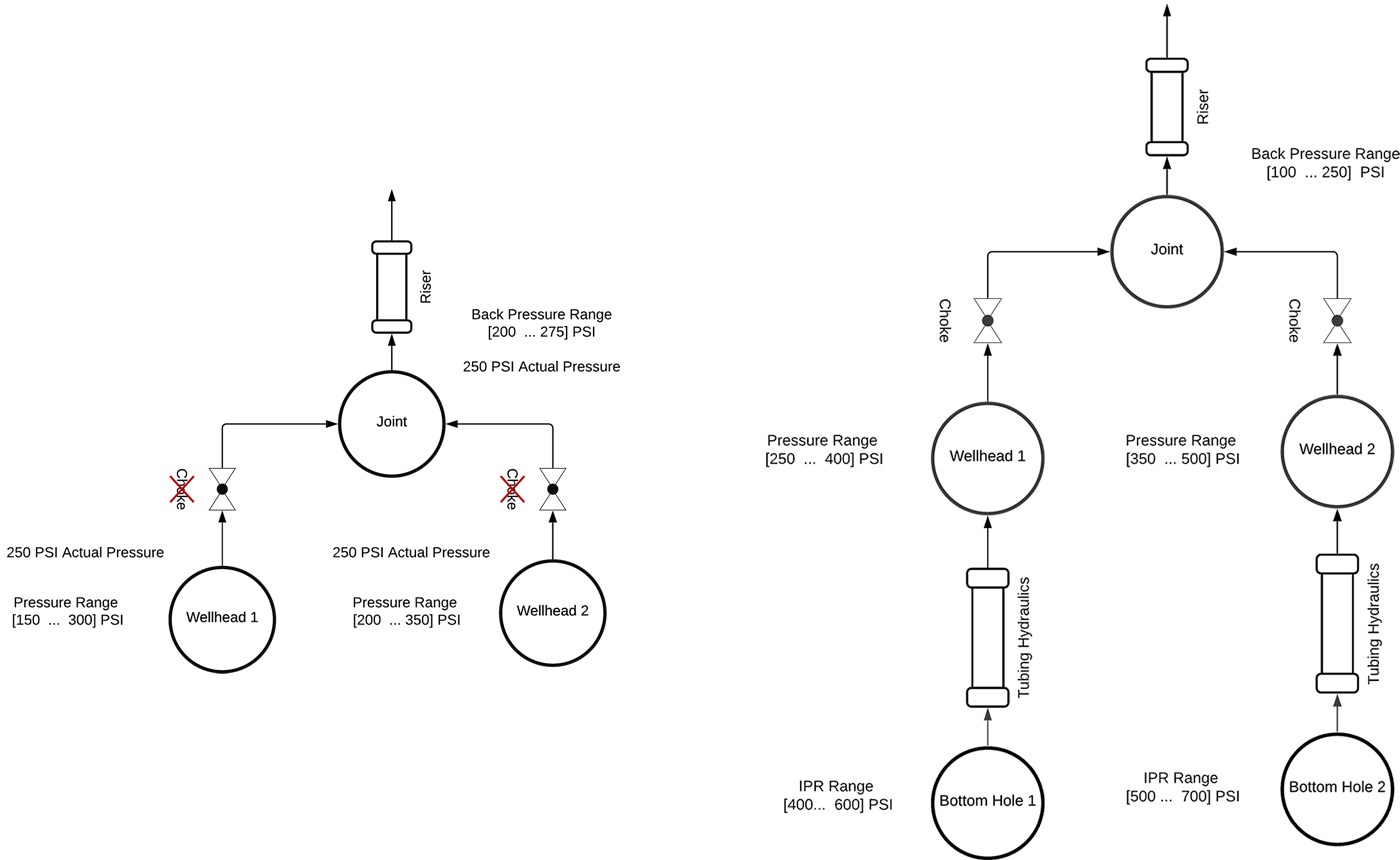

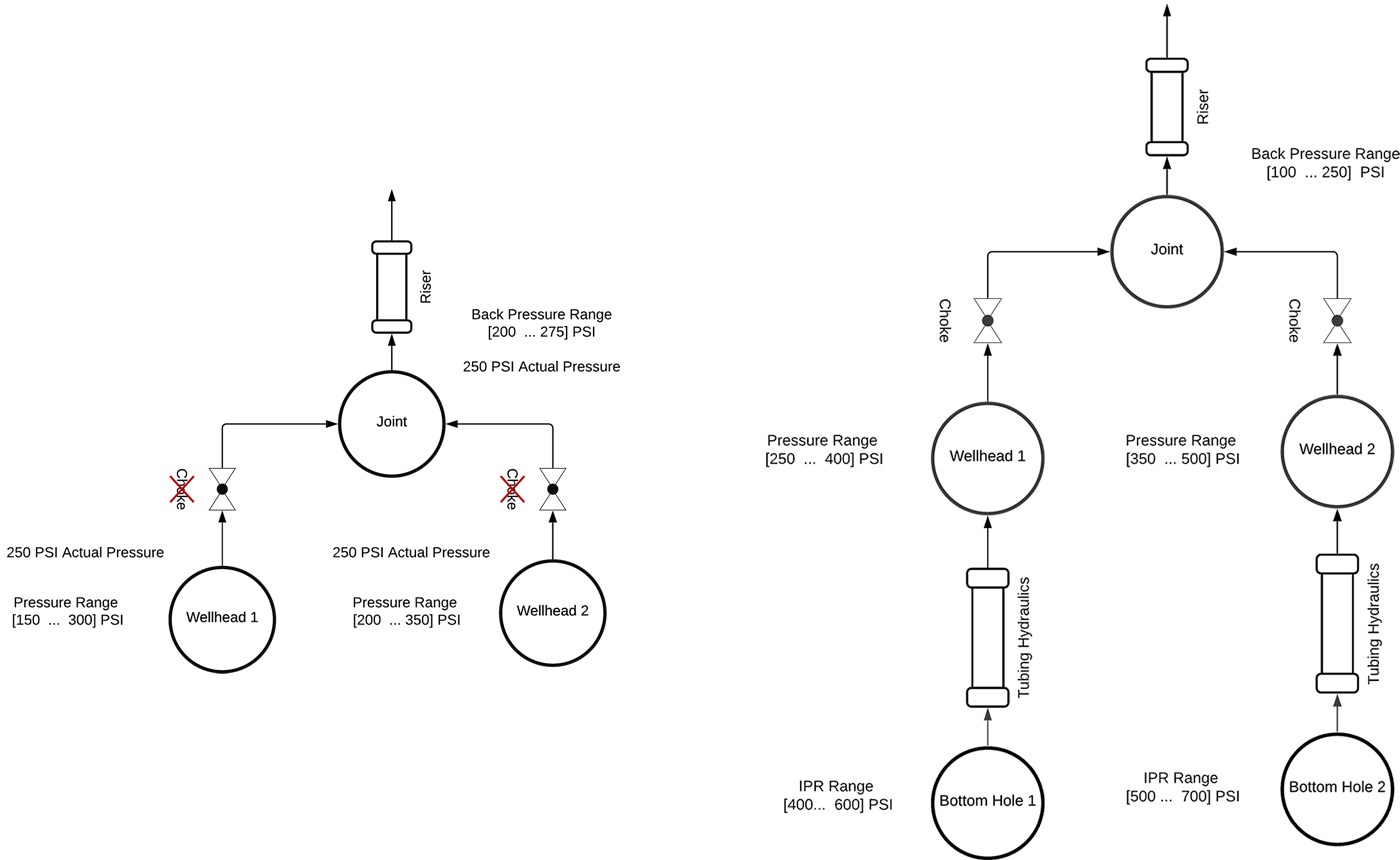

Figure 1 below shows a simple example of two wells whose current state allows for a wide range of allocation without back pressure being an issue. If the pressure in the reservoir declines and the pressure drop over the riser increases due to a higher water content, then the chokes may have to be fully opened, and both wells experience a limited operating range due to the network back pressure (Figure 2).

Figure 1 (left): Two wells connected to a riser. Figure 2 (right): Wells experiencing back pressure.

ECHELON’s FNS solves a system of steady-state rate and pressure balance equations for a surface facility network with a given flow direction. The network represents either a single production or injection flow stream. Production flow streams consider three phases at surface conditions (oil, gas, and water), while injection streams model a single phase (gas or water). The nonlinear balance equations are solved using a damped Newton-Raphson scheme that employs a sparse direct solver for the computation of the step direction. Multiple stream instances can be active at the same time, allowing for simultaneously solving multiple injection and production problems.

The ECHELON facility network solver FNS can be operated either in standalone mode as a dedicated program, or as an integrated part of ECHELON. The standalone program can be used by the reservoir engineer to test new network configurations or analyze difficult cases, while the coupled mode is used to provide back pressure information to the field scheduler during simulation runs. Engineers may choose between three coupling frequencies: periodic (at pre-specified time steps), time-step (at every timestep, and lagged iterative (at Newton iteration level for ECHELON’s solver). In many cases, a periodic coupling is entirely sufficient to achieve results that are close to time-step or lagged iterative coupling.

FNS can be coupled to both black-oil and compositional ECHELON simulation models. In both cases, correlations using surface rates at standard conditions are used to compute hydraulic pressure drops via industry standard Vertical Flow Performance (VFP) tables. Alternatively, pipelines with constant pressure drop can be used to simulate simple (fixed) chokes or pumps. FNS also supports flow bifurcation with an arbitrary number of parallel bypass pipes. Inoperable wells or pipes are shut-in, and it is left to the field scheduler to reopen them at the next invocation of FNS or at a later time.

Even when coupled with FNS, the solution to the well allocation problem computed by ECHELON’s field scheduler may (in rare cases) be unattainable in the real world. As a trivial example, consider a group of wells being connected to a riser, subject to a 50% flow reduction due to a group or field constraint violation. Having an estimate for the individual well operating ranges, the field scheduler reduces high GOR wells because the field also produces too much gas. While this heuristic makes sense if we want to maximize oil production, abide by the constraint, and reduce overall gas production, it may rob the riser of the necessary gas to sufficiently bubble up the fluid. As a result, the riser may stop flowing due to excessive liquid holdup. Even if ECHELON feeds back the well allocation to FNS, e.g. as well boundary condition, FNS could only report that it had to shut-in the wells, leaving the field scheduler in the dark about what went wrong. To address situations like this Stone Ridge Technology is integrating a numerical optimization capability into FNS with the goal to perform the allocation directly inside the facility network solver. In this case, FNS reports back the actual solution instead of providing ECHELON with the well operating ranges.

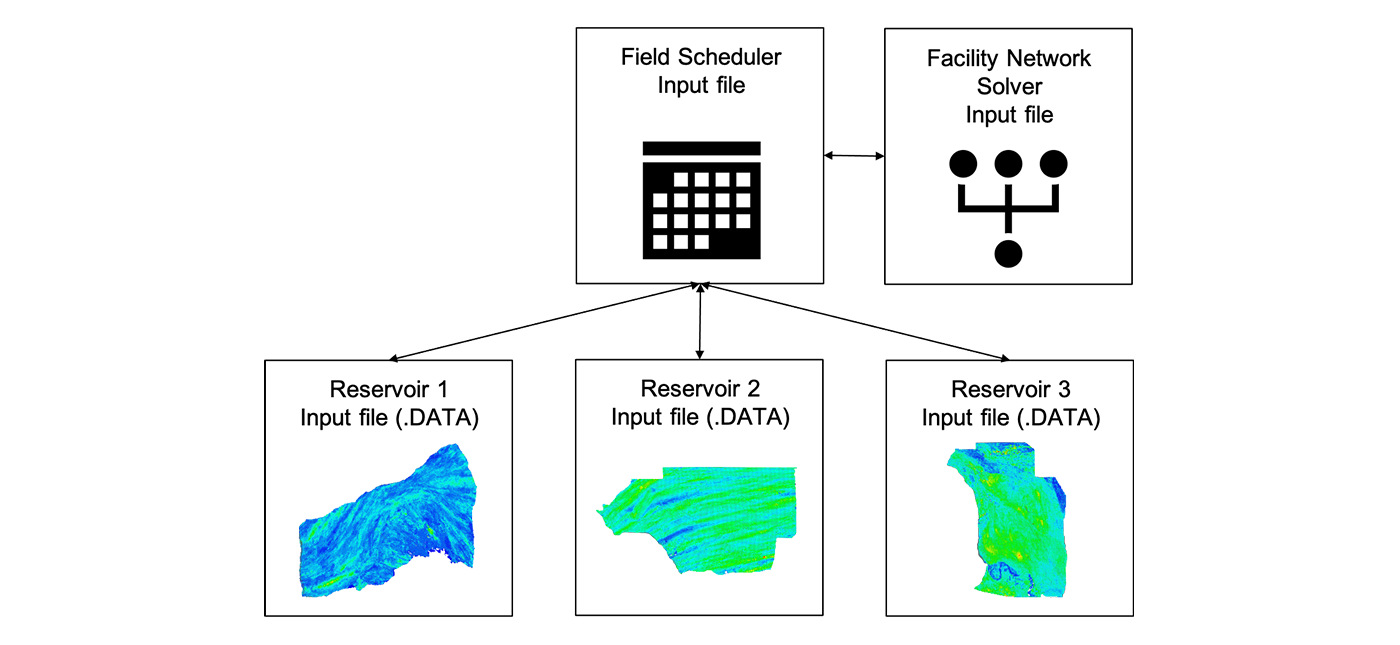

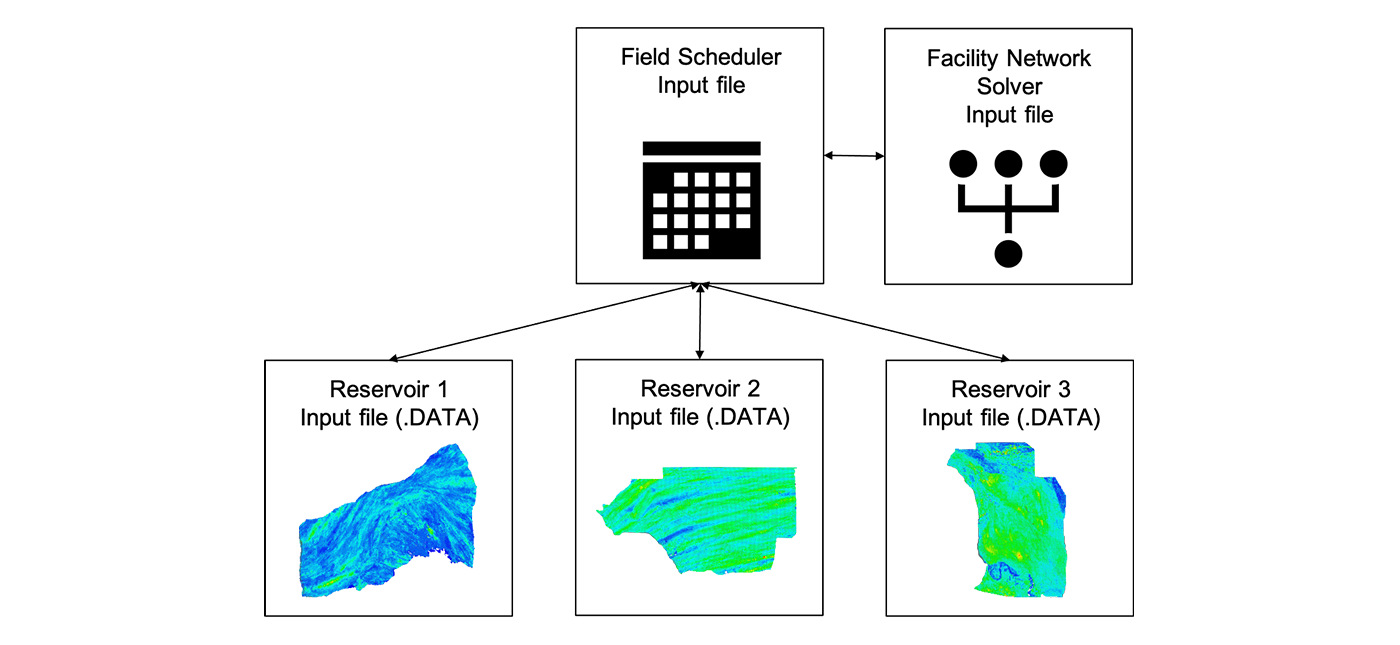

We use ECHELON to model a real asset consisting of three dry gas reservoirs coupled via a surface facility network. Each of the reservoir models has about 1M grid cells and uses a black-oil fluid model. A total of 68 wells are connected to the production network. ECHELON allows for the seamless integration of the individual reservoir models into a single coupled simulation model with shared surface facilities. Figure 3 depicts the coupled simulation model’s input data structure.

Figure 3: Main Input Data Blocks for Coupled Simulation Model

The well allocation problem to be solved by the field scheduler is as follows. Wells from different reservoirs are collected into three groups, each group contains wells from more than one reservoir. Each of the groups has its own target plateau rate, whereas the gas production rates of the individual reservoirs have to adapt to the group constraints. Figures 4 and 5 show the simulation results with reference to the group rates and the individual reservoir rates, as well as the total field rate.

Figure 4 (left): Group Production Rates and Field Rate. Figure 5 (right): Reservoir Production Rates and Field Rate

In the figures above, the dashed lines are from a simulation run without FNS coupling, whereas the solid lines are from the coupled simulation run. One can see clearly that the plateau phases of the three groups are shorter in the coupled simulation run, and that the total field production rate drops off earlier - leading to a slightly reduced overall gas production.

Please see the ECHELON case study MARACUYA for more information.

ECHELON’s FNS provides surface facility network simulation capabilities and feedback to the simulation engine. The information is used by ECHELON’s field scheduler to perform more realistic well allocation by accounting for network back pressure and well choke settings. FNS has been designed for high computational performance with no impact on ECHELON software’s speed and simulation turnaround time. An optimization capability is presently under development and will be released next year.

We thank Eni S.p.A for the permission to publish the data contained in this blog article.

Klaus Wiegand

Klaus Wiegand is Senior Scientific Advisor at Stone Ridge Technology. Prior to joining SRT Klaus developed numerical reservoir simulation software at ExxonMobil where he spent 22 years. Klaus has a Masters degree in Computational and Applied Math from Rice University.