Unconventional Reservoir Evaluation with ECHELON Reservoir Simulation Software

ECHELON reservoir simulation software can handle complex fluid models in unconventional reservoirs on fine grids while delivering extraordinary performance.

ECHELON reservoir simulation software can handle complex fluid models in unconventional reservoirs on fine grids while delivering extraordinary performance.

Posted in: ECHELON Software

Oil production from unconventional reservoirs has increased significantly over the past decade and accounts for more than half of the total oil production in the US. One of the main challenges in these exceptionally low permeability plays is maintaining production, as individual wells tend to exhibit a steep decline with time. Primary recovery in unconventional reservoirs varies but is generally less than 10% according to the Energy and Environmental Research Center (EERC).

Operators are always seeking new technologies to enhance this recovery, and while many technologies have proven to be effective, the cost associated with these methods is often substantial. A careful, quantitative assessment is needed to determine if the incremental production will outweigh the additional cost. It has been found, for example, that the miscible injection of previously produced gas can reduce oil viscosity and hence enhance production in some formations. Injecting CO2 can frequently provide even more enhancement, but often at a significantly higher cost. Assessing these types of recovery techniques requires tools which allow reservoir engineers to balance cost and efficacy to define the best strategy in the field.

Reservoir simulation can provide a fast and economical way to assess the promise of new recovery strategies before committing significant capital to a pilot study. Furthermore, it can be used to help optimize operational parameters such as injection rate, duration and soak time and to assess the relative impact of the gases available for injection. In order to have an accurate estimate for this recovery approach, a compositional model is often needed. One of the main challenges in this type of model is to have fast simulation turnaround without compromising the accuracy and quality of the models.

At Stone Ridge Technology, we have developed ECHELON software, a reservoir simulator able to handle complex fluid models in unconventional reservoirs on fine grids, while delivering extraordinary performance. ECHELON is the first commercial reservoir simulator to harness the computational power of GPUs and fully exploit their massive parallelism. It has disrupted the oil and gas industry by demonstrating unprecedented performance on large real field asset models covering a wide range of complex features. It has been extensively tested and used on conventional and unconventional compositional models.

As noted above, processes like huff and puff cycle injection of hydrocarbons or CO2 can be applied to boost the oil mobility in the low permeability pore spaces. ECHELON reservoir simulation software can easily handle complex huff and puff models, with a large number of components and detailed hydraulic fractures by using local grid refinements (LGRs). ECHELON's capabilities and performance are demonstrated here in three unconventional models used in huff and puff projects.

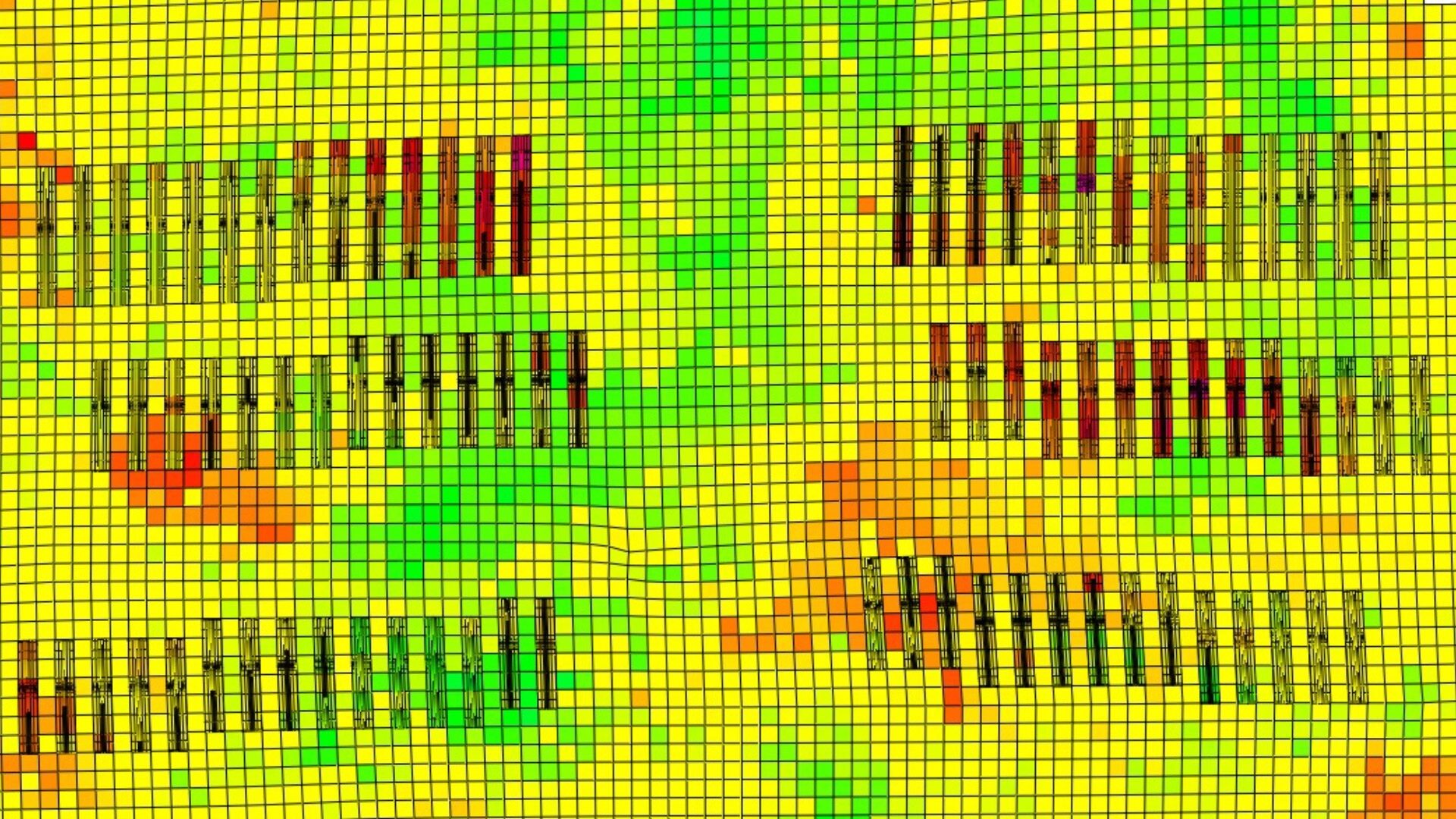

The first case represents a single well with a complex fracture network modeled as a dual permeability model as shown in Figure 1. The fluid is described by a Peng Robinson equation of state with 13 components. The model was history matched using two years of daily production data from primary depletion and used for sensitivity studies in the huff and puff process. The runtime of the model was prohibitive using a legacy CPU based simulator, whereas ECHELON can run the case in just a few minutes using only one GPU.

Table 1 – Runtime comparison between ECHELON and a legacy simulator

Figure 1 – Permian basin complex fracture network

The Fracture Template Workflow (FTW) is an ECHELON software feature that eases the time consuming workflows associated with modeling unconventionals. A user can quickly incorporate well trajectories and hydraulic fracture geometry into a reservoir simulation model by using FTW. Using a few geometric parameters that describe the fracture, ECHELON reservoir simulation software generates logarithmic local grid refinements (LGRs) around each planar fracture and eliminates the need to use an external modeling tool. This feature can be very powerful while performing assisted history match, sensitivity analysis or optimization on fracture design.

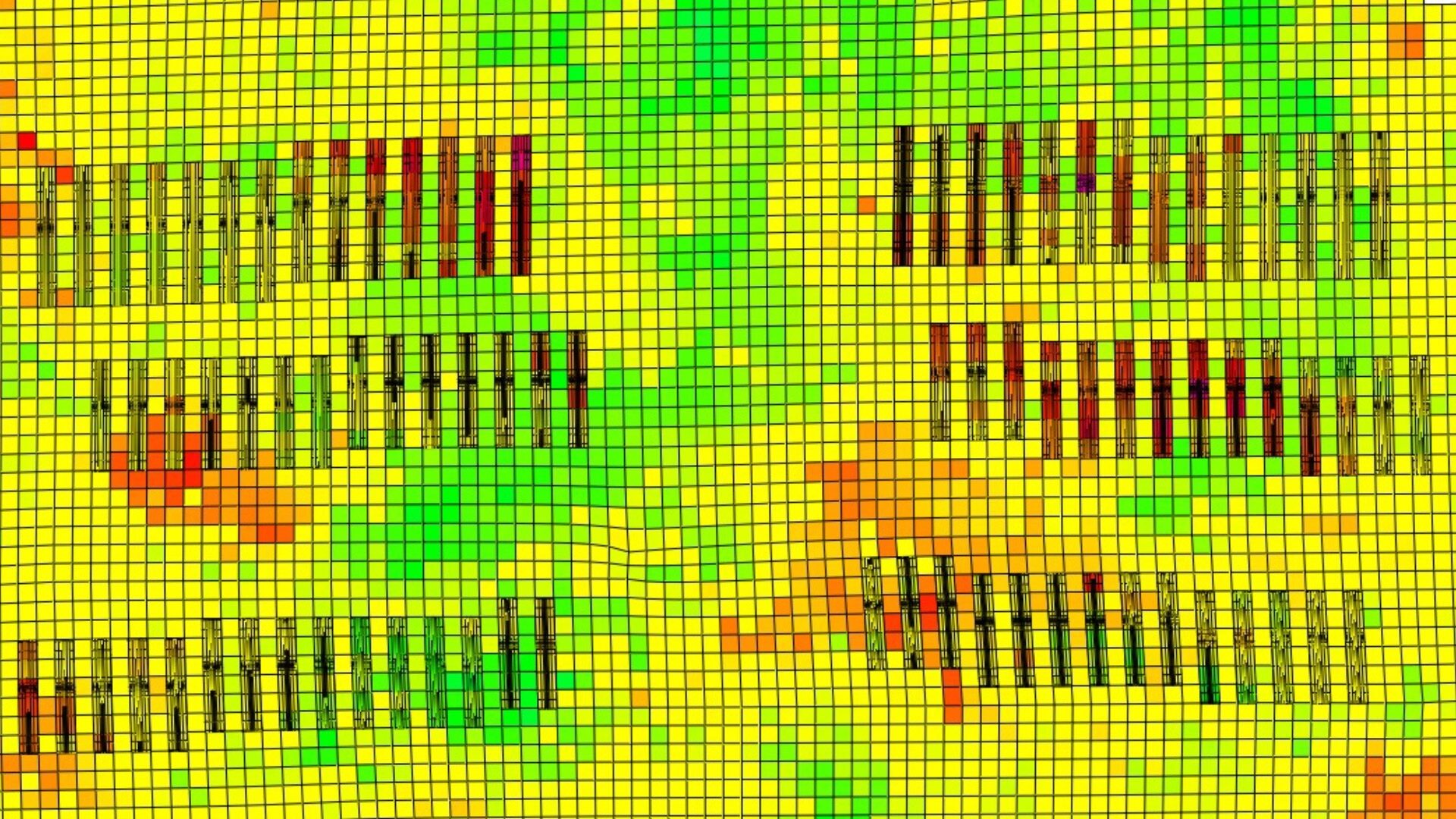

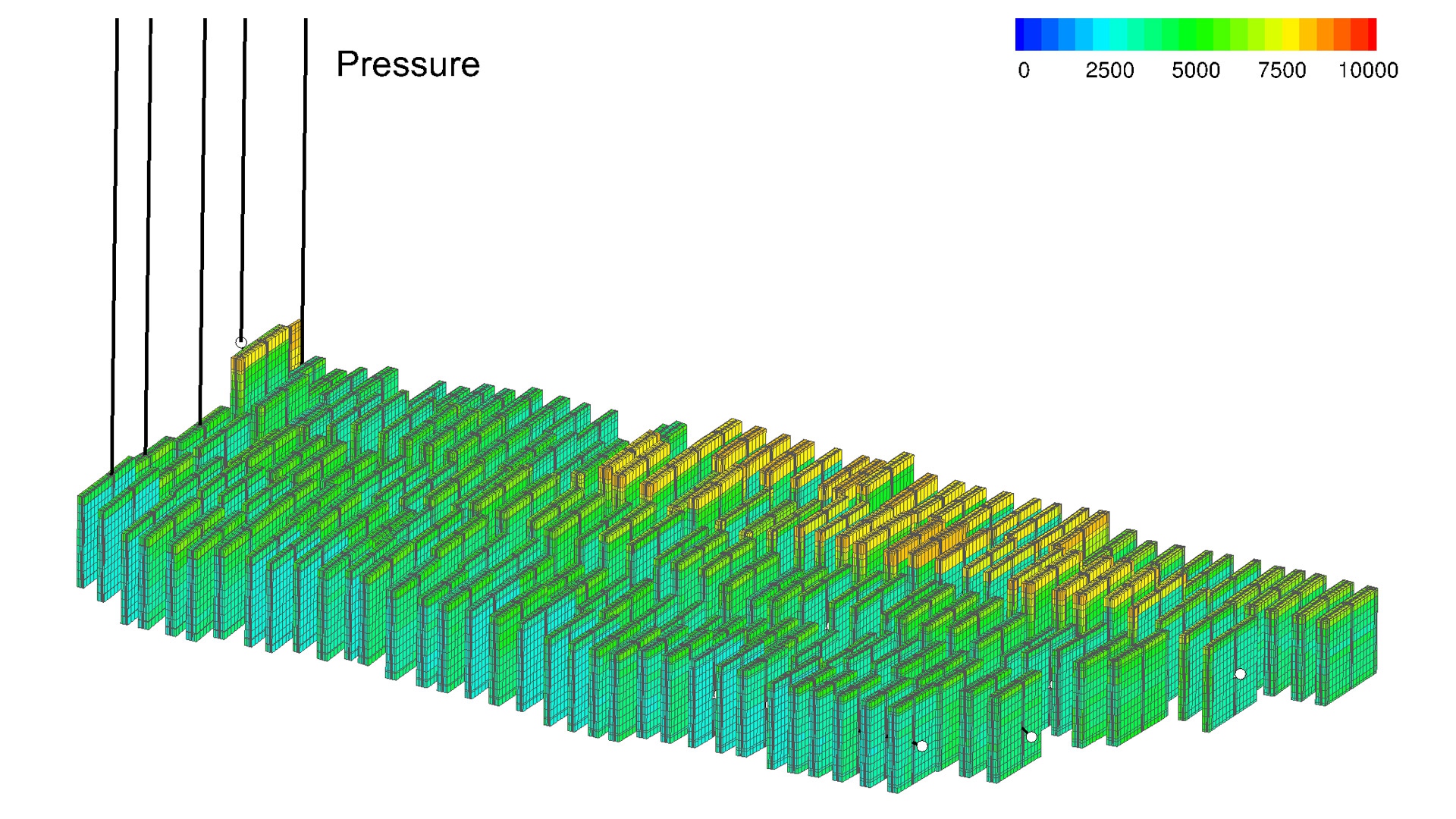

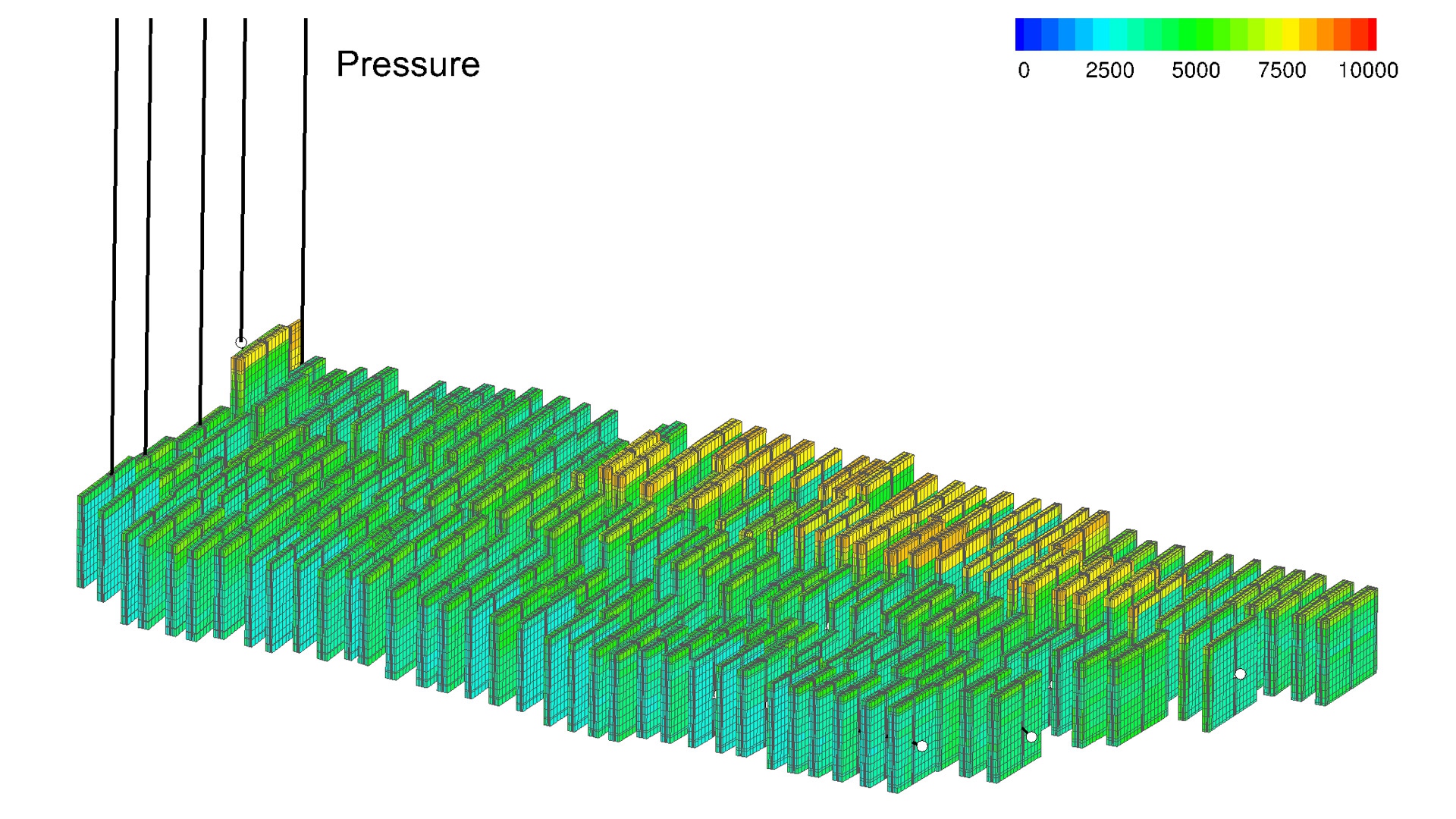

In a second case, an EOR study was carried out on an Eagle Ford asset (see Figure 2). It was believed that the fracture geometries are mostly planar, and the model was developed using FTW in ECHELON software. Five horizontal wells were history-matched to the 5 years of daily production data in primary depletion, followed by one year of huff and puff cycles. The cycles were 30 days each with no soaking time in between. Historically, this type of study would have been carried out using black oil simulation, as compositional cases would be too computationally demanding. However, ECHELON reservoir simulation software can run the compositional case in under an hour, less than three times the black-oil model runtime (See Table 2). Note that the blackoil PVT was equivalent to the compositional EOS.

Table 2 – Blackoil and compositional runtime for ECHELON software

Figure 2 – Eagle Ford multi well pad with planar fractures

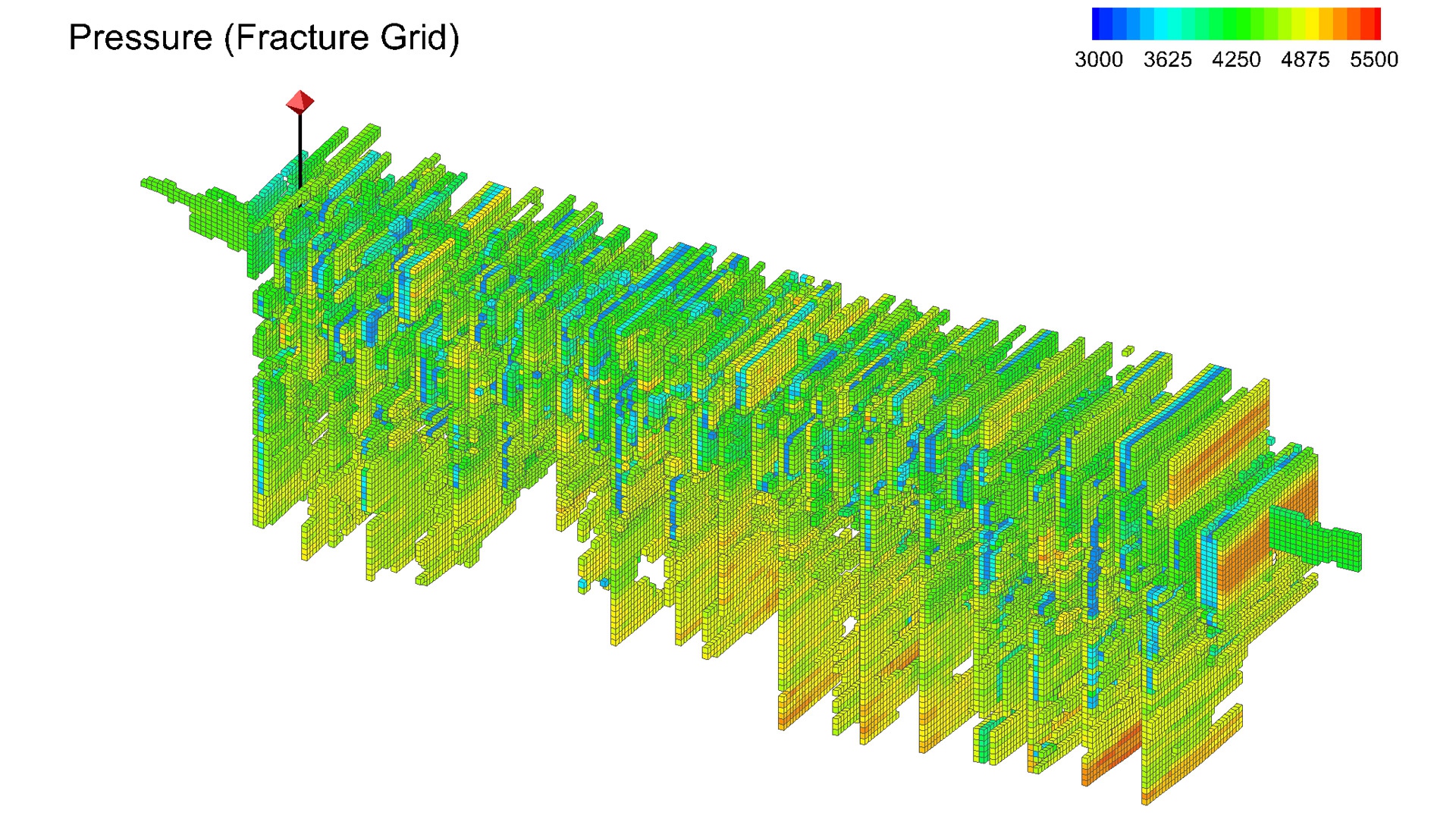

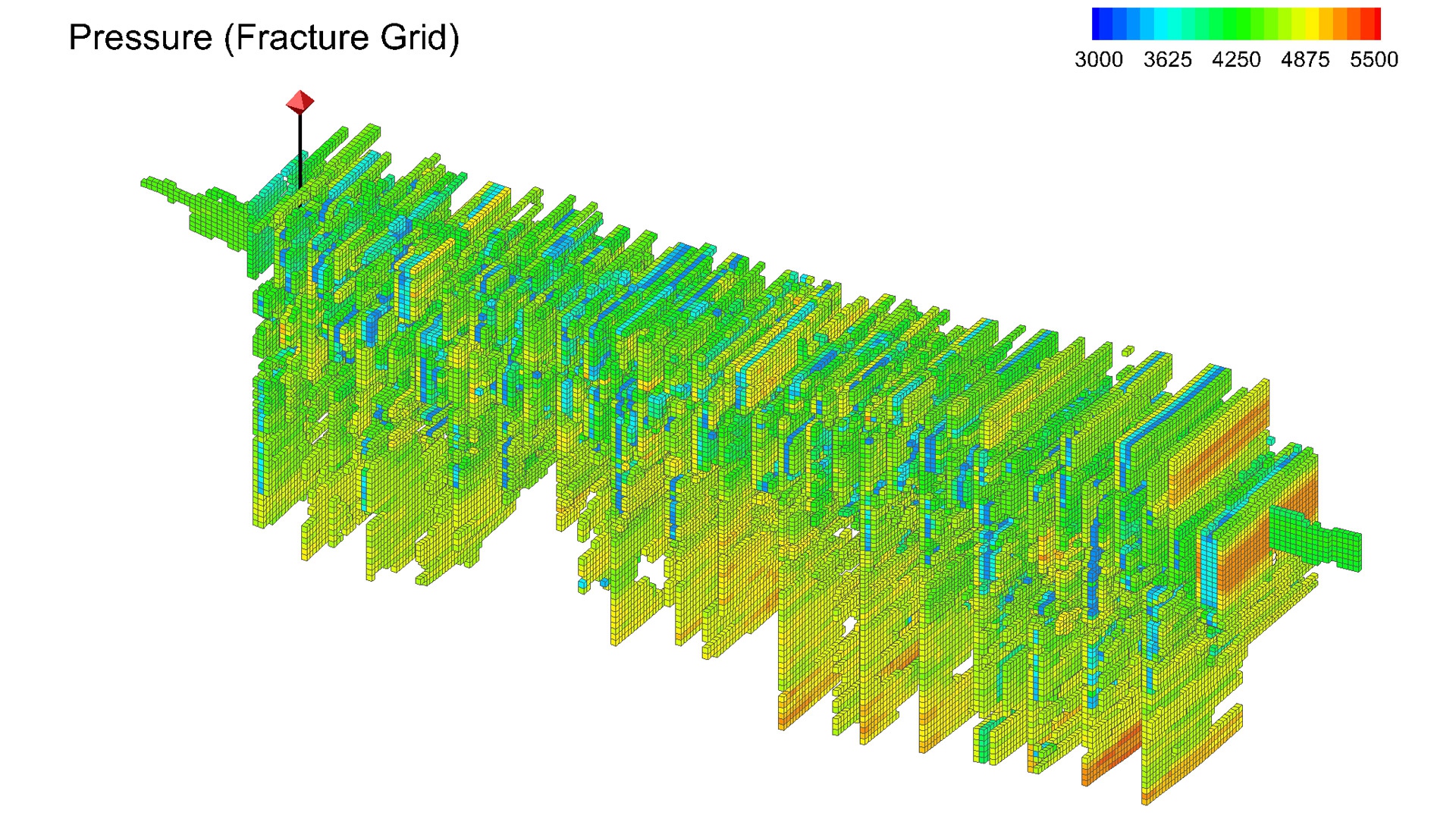

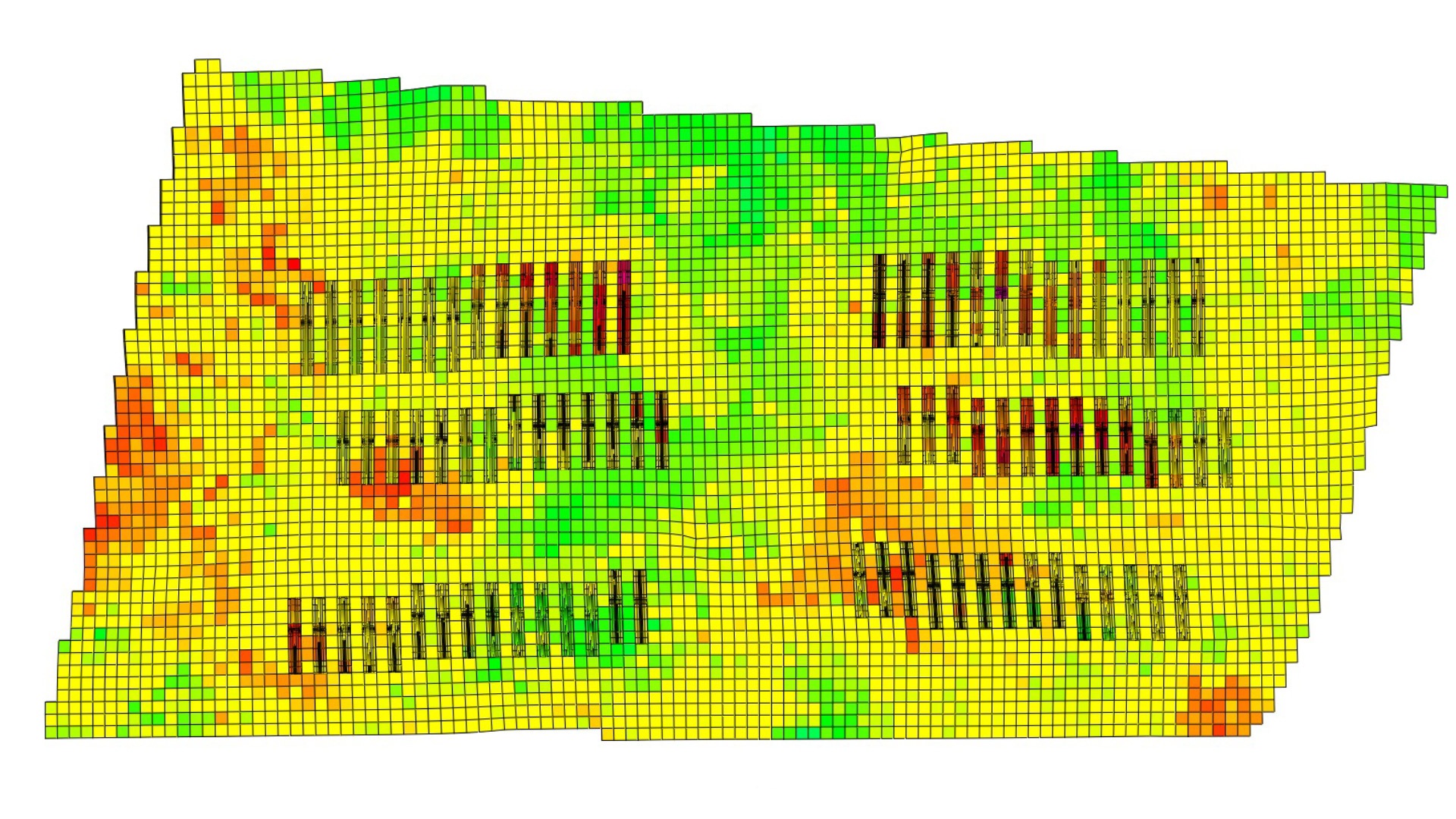

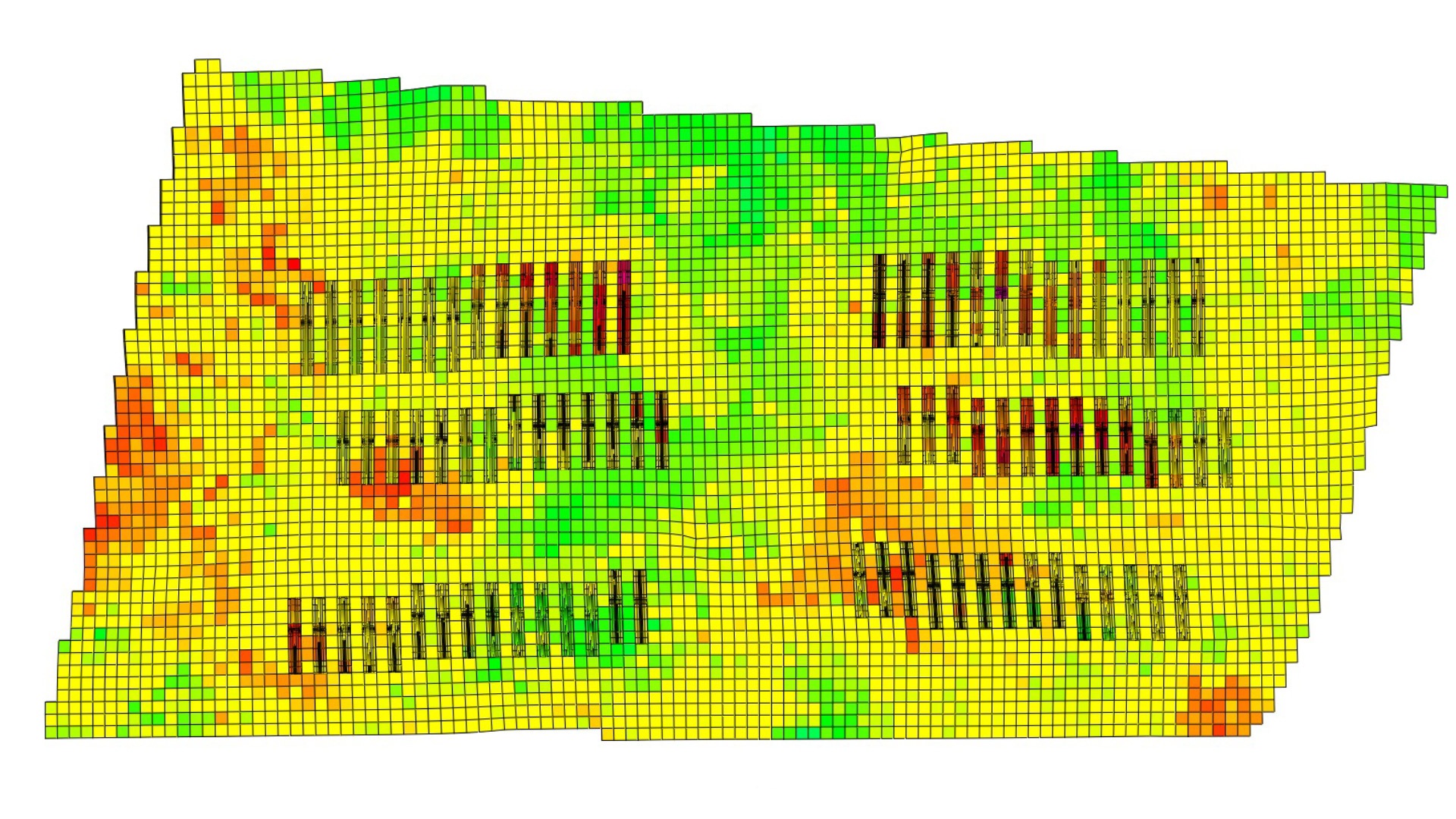

To demonstrate the value of using ECHELON software and the FTW for unconventional resources, a sensitivity analysis was carried out on the key parameters impacting oil recovery in the huff and puff process. For this case, the sector reservoir model has around 400,000 cells and 6 horizontal wells. The fluid model was compositional, represented by 8 components.

Figure 3 – Grid showing the reservoir permeability and 6-wells pad with hydraulic fractures (Local Grid Refinements)

A full sensitivity analysis was carried out varying the fracture height, half-length and permeability(using FTW) along with the CO2 injection rate.

The FTW feature in ECHELON software allows users to easily and quickly define hydraulic fractures, enabling the application of more comprehensive and automated generation of cases for sensitivity analysis. The fracture geometry (height up/down and half-length right/left) and properties (Kx, Ky, Kz) were permuted and mixed to generate 30 cases representing multiple fracture configurations that might capture the reality of the hydraulic fractures in the reservoir.

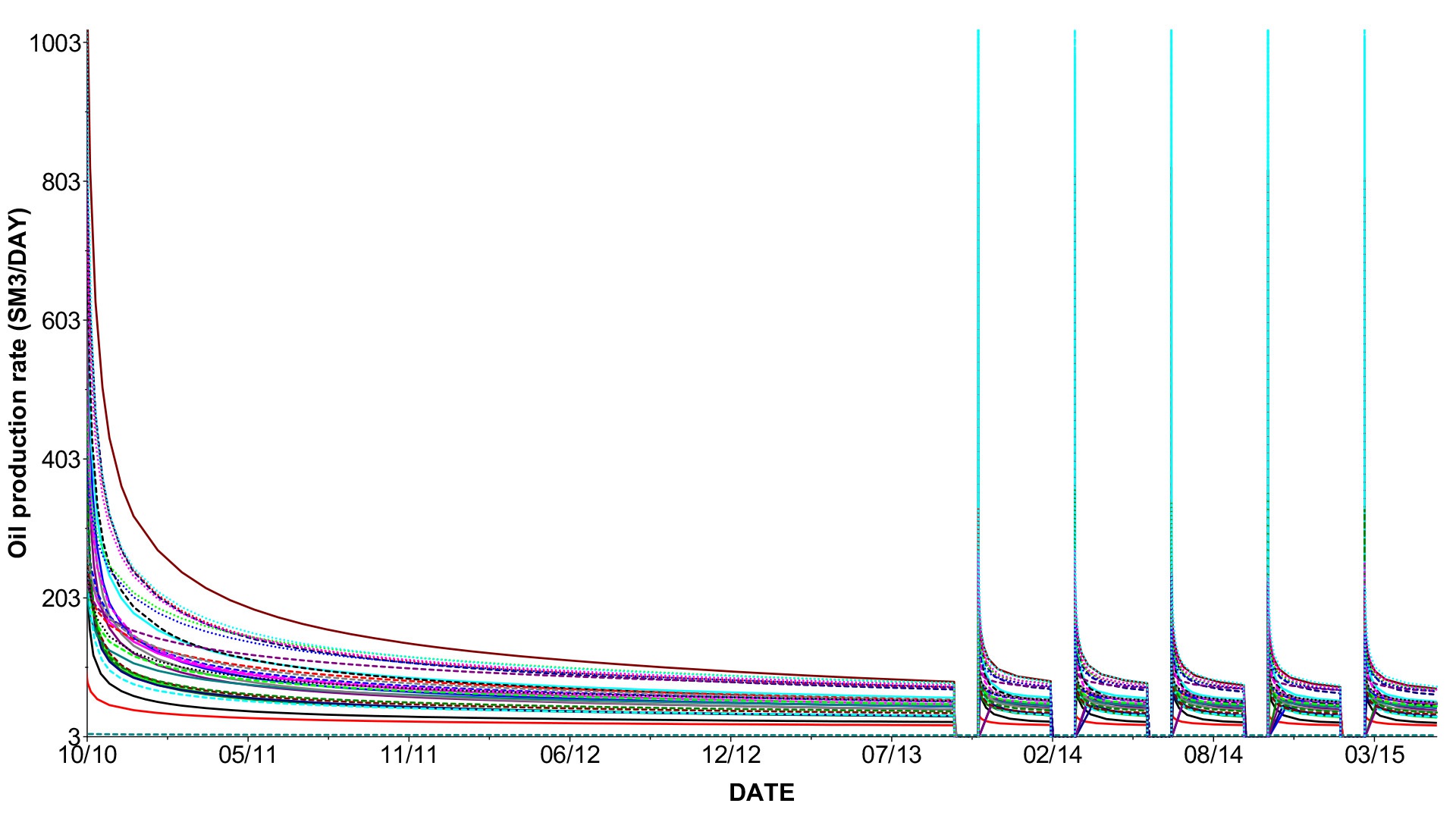

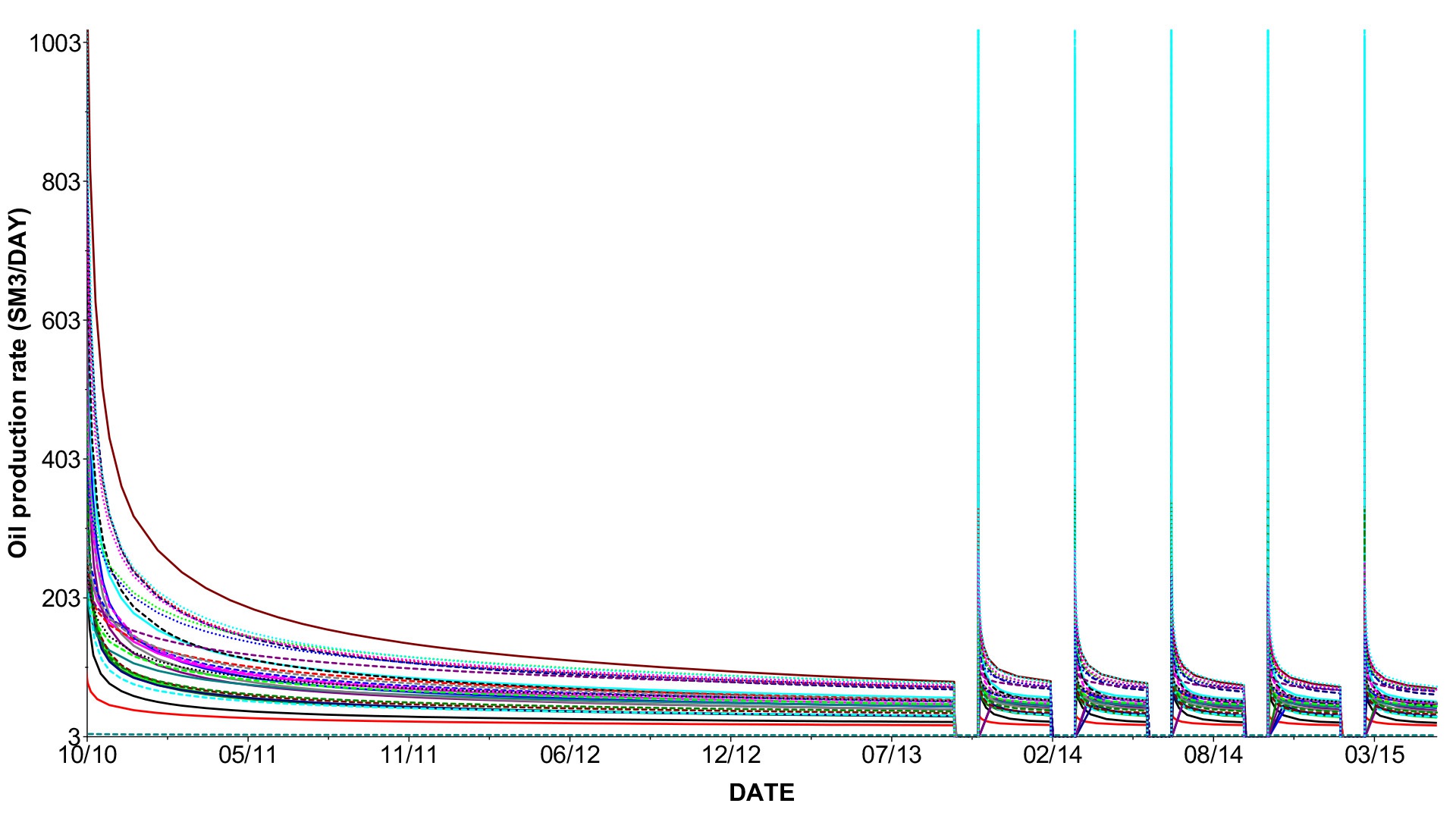

Figure 4 shows the oil production curves for all the simulation scenarios (30 cases). For just less than 3 years the wells were under natural depletion, then a CO2 huff and puff injection started. The effects of the fracture properties can be observed in the first year of production (primary depletion).

Figure 4 also shows the effects of the CO2 injection rate over the oil production during the 4th and 5th year, giving an idea of the expected production potential if a CO2 huff and puff injection is performed.

It is also important to note that all the simulation cases took around 6-9 minutes to run in ECHELON reservoir simulation software using only 1 laptop GPU and the full sensitivity analysis was performed in less than one working day.

Figure 4 – Sensitivity analysis on fracture geometry and injection rate in huff and puff process

In conclusion, ECHELON reservoir simulation software provides a robust framework for quick hydraulic fracture modeling and simulation that can be easily applied to an unconventional field. With its exceptional performance, ECHELON software is able to rapidly generate and run hundreds of hydraulic fracture cases in a matter of minutes, allowing operators to simulate the effects of the hydraulic fractures and make the right operating decisions.

Thank you to Jose Pina for his great contribution to this blog article.

Reza Ghasemi

Reza Ghasemi is a senior reservoir engineer at Stone Ridge Technology, where he works primarily as a customer support for deploying ECHELON software. He is also involved in developing and testing new features. He received his BSc and MSc in electrical engineering from Isfahan University of Technology and holds a PhD degree in petroleum engineering from Texas A&M University.